Uflex achieves low ink GSM

Uflex’s cylinders business announces low ink breakthrough with its modification and optimization of rotogravure cell structures.

Uflex achieves low ink GSM by modifying and optimizing rotogravure cell structures

After an intense R&D of almost three years, the cylinders business of India’s largest multinational flexible packaging materials and solution company, Uflex, said it has been able to optimize cell structures of laser engraved rotogravure cylinders to an extent that can actually result in about 20-25% less ink consumption than what the electro-mechanically engraved counterpart would require in order to render the same image resolution and enhancement.

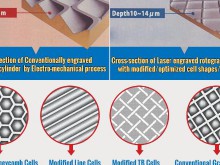

Unlike Electro-mechanical engraving which produces a conventional cell shape, Laser engraving offers immense flexibility towards altering cell shapes and structures for the rotogravure cylinders. This is the fundamental reason that results in low ink GSM while printing on the substrate.

To understand this point better, it is rather important to have a quick recapitulation about the roll the typical cells of a rotogravure cylinder play during the printing process: The ink is picked up by the cylinder and transferred on to the substrate. The rotogravure cylinder is immersed in the ink sump and during the process of printing the recessed (engraved) cells pick up the ink. The substrate gets sandwiched between the impression roller and the gravure cylinder. At this juncture the ink gets transferred from recessed cells to the substrate by capillary action.

Explaining the recent break-through of lesser ink consumption in rotogravure printing, Mr. P.K. Agarwal, joint president, cylinders business, Uflex, said, “On the laser engraving set-up, our team has been able to create various modifications on honeycomb cell structure, line cell structure, TB cell structure and others which in turn during the print run render solid backgrounds, coating with high & low depths, other specialized coatings, vignettes, half tone images among several others. It is all about the shape and structures of the cells that we have been able to modify and optimize through the process of laser engraving. This is not possible in electro-mechanical engraving which can only produce conventional cell shape/structure.”